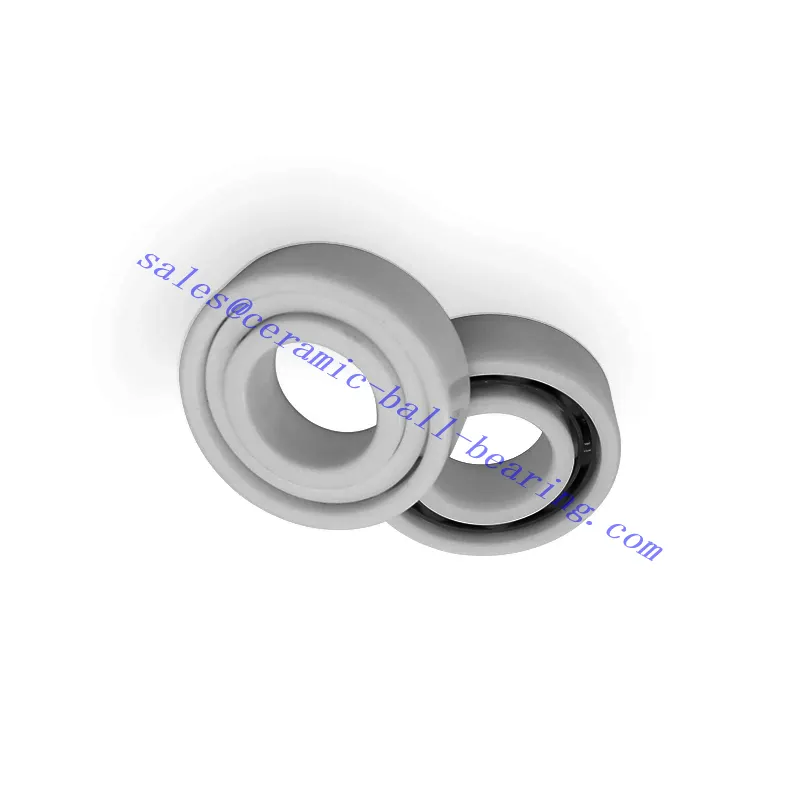

Sealed Full Ceramic Ball Bearing 6003-2RS ZrO2/Si3n4

As one of the ceramic ball bearing manufacturers, suppliers, and exporters of mechanical products, We offer ceramic ball bearing and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of ceramic ball bearing.

Sealed Full Ceramic Ball Bearing 6003-2RS ZrO2/Si3n4

6003-2RS ZrO2/Si3n4 SRL Ball Bearing17x35x10 6003-2RS ZrO2/Si3n4 Bearing, the inner diameter is 17mm, the outer diameter is 35mm, and the width is 10mm. This is a popular size that could be used in many applications. The bearing is made of Ceramic. The ball bearing grease is recognized as “standard” throughout the world. Excellent low noise profile and long-life grease usable over wide temperature ranges.

Item: 6003-2RS ZrO2/Si3n4 SRL Ball Bearing

Type: Full Ceramic Ball Bearing

Balls: Si3n4 (Silicon Nitride)

Ceramic Inner/outer races: ZrO2 (Zirconium Oxide)

Ceramic Wide

Temperature Range: -50~150

Dimensions: 17mm x 35mm x 10mm/

Metric Lubrication: SRL high-quality grease

ID (inner diameter)/Bore: 17mm

OD (outer diameter): 35mm Width/Height/thickness: 10mm

Size: 17mm x 35mm x 10mm

Quantity: One Bearing

Wide Temperature Range: -50~150 C (-58~302 F)

Ceramic Ball Bearing Features:

- Item: 6003 Ball Bearing

- Type: Full Ceramic Ball Bearing

- Cage: PTFE

- Balls: ZrO2 Ceramic

- Inner/outer races: ZrO2 Ceramic

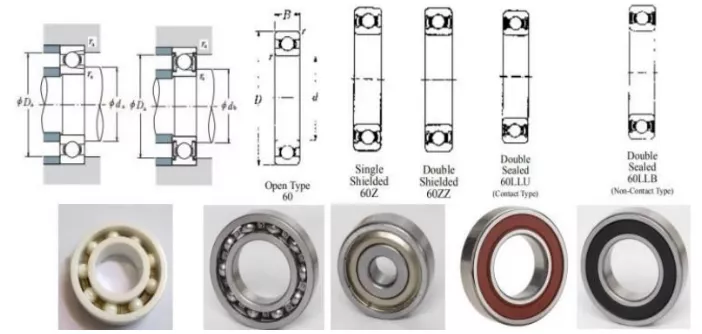

Types of Ceramic Ball Bearing:

1.Si3N4 bearing ball

Characteristic: resistant to strong acids, strong alkalis, salt, and gas of deleterious, long contact fatigue life, high hardness, and resistance to wear.

2.ZrO2 bearing ball

Resistant to strong acids, alkalis, salt, and gas of deleterious, long life, high hardness, exceptionally resistant to wear, and high modulus of elasticity.

3. Title Al2O3 bearing ball

Resistant to strong acids, strong alkalis, salt, and gas of deleterious, long life, high hardness, resistant to wear, resistant to high temp up to 1400°C.

4. Stainless Steel bearings

Based on clean, ss bearing has the excellent property: High precision, Wear resistant the same as High Carbon Chrome steel bearing.

5. Full ceramic bearing

The full Ceramic bearing has good performance: Non-Magnetism Electrical insulation, Wear-resistant, Anti-corrosive, Self-lubricated, and high-Temperature usage.

6. Full Ceramic Si3N4 bearings

Full ceramic ball bearing is more suitable for higher temp and load applications. It is also applied at high speed and high precision, and the highest precision Abec-7 can be achieved.

|

Bearing

Part No.

|

Boundary Dimensions

|

Mass(KG)

|

|||||

|

ID(mm)

|

OD(mm)

|

Width(mm)

|

ZrO2

|

Si3N4

|

Plastic

|

440C

|

|

|

6000

|

10

|

26

|

8

|

0.014

|

0.0075

|

0.0035

|

0.018

|

|

6001

|

12

|

28

|

8

|

0.017

|

0.0092

|

0.004

|

0.019

|

|

6002

|

15

|

32

|

9

|

0.024

|

0.013

|

0.006

|

0.0031

|

|

6003

|

17

|

35

|

10

|

0.032

|

0.017

|

0.008

|

0.041

|

|

6004

|

20

|

42

|

12

|

0.052

|

0.028

|

0.013

|

0.068

|

|

6005

|

25

|

47

|

12

|

0.061

|

0.033

|

0.015

|

0.079

|

|

6006

|

30

|

55

|

13

|

0.089

|

0.048

|

0.022

|

0.116

|

|

6007

|

35

|

62

|

14

|

0.12

|

0.063

|

0.029

|

0.15

|

|

6008

|

40

|

68

|

15

|

0.15

|

0.08

|

0.037

|

0.19

|

We also offer other ceramic ball bearings, such as 6008 ceramic ball bearings and a series of custom bearings.

Full Ceramic Ball Bearing:

Ceramic Ball Bearing Advantages:

One of the main advantages of ceramic bearings over bearings made of other materials is their high heat resistance. Ceramic bearings perform well at temperatures where other materials lose their mechanical properties. Ideal applications for these properties are: medical devices, chemical fiber instruments, and some aircraft components. In contrast, ceramic bearings can also provide rolling elements in low-temperature environments such as liquid oxygen.

The non-magnetic properties of ceramic bearings make them suitable for high magnetic field exposure applications. These include superconductor and semiconductor equipment, aircraft components, electron beam processes and other sensitive instruments.

Ceramic bearings are light weight and therefore help to reduce the overall weight of the product. Very effective applications for its lightweight are aerospace equipment and components, as well as motorcycle crankshafts. Reducing weight reduces the effects of vibration and stress in unbalanced applications and also increases speed and efficiency.

The hardness and stiffness of ceramic bearings are important to ensure that bearings can withstand loads. The hardness and stiffness of these bearings is greater than that of other bearing materials used. This means that ceramic bearings have higher wear resistance and therefore longer service life. This is essential for all different types of bearing applications; Including machine tool spindles, turbochargers, gas turbines, vacuum equipment and motors, etc.

Other Types of Sic Ceramic Ball Bearing:

Loose Ceramic Balls 1.5mm 2mm 3mm and other size SiC, this is a popular size that could be used in many Bicycle, or any application that uses this size 4mm.Ball is made of Ceramic SiC.

Ceramic Ball Bearing Knife:

- 18 Ceramic Ball Bearings For Smooth And Highly Reactive Blade Deployment

- 2.7mm Solid Piece 3K Black Carbon Fiber Scales For Lightweight Durability

- Carbon Fiber Scales Are Textured Around The Edges For Added Grip

- Blade Length: 3.63″, Closed Length: 4.63″, Knife Weight: 4.7 oz.

- 1.4116 German Cutlery Steel Blade

- 55-57 Rockwell Hardness Tested and Proofmarked

- Modified Drop Point Blade With Jimping On Spine

- Folding Knife With Linerlock Design, Pocket Clip

Ceramic Ball Bearing Application: