Ceramic Ball Bearings

Ceramic Balls (made of silicon nitride, zirconia oxide, silicon carbide and alumina oxide) are kept in our stock series. They are advantageous in having a longer service life, lower friction resistance, higher seizure resistance, higher corrosion resistance, higher rigidity, higher temperature resistance ( up to 800C) lightweight (40% of bearing steel), non magnetic, and insulated.

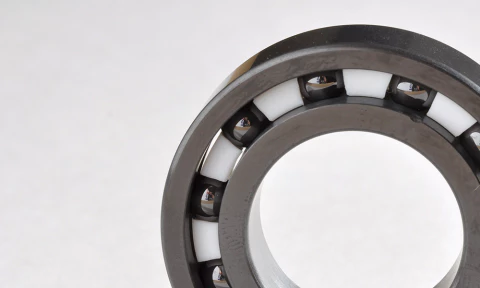

Hybrid Ceramic Ball Bearings

Ortech advanced hybrid ceramics ball bearings have steel inner and outer rings and rolling elements made from Silicon Nitride.

Silicon Nitride( Si3N4) is a ceramic material with properties including high hardness, electrical insulation and low density. Ortech produce silicon nitride balls and cylindrical rollers that feature a higher level of accuracy than steel ball materials. Therefore hybrid ceramic ball bearing have many excellent performance such as heat resistance, extended life, light weight, lower thermal expansion and electrically non-conductive.

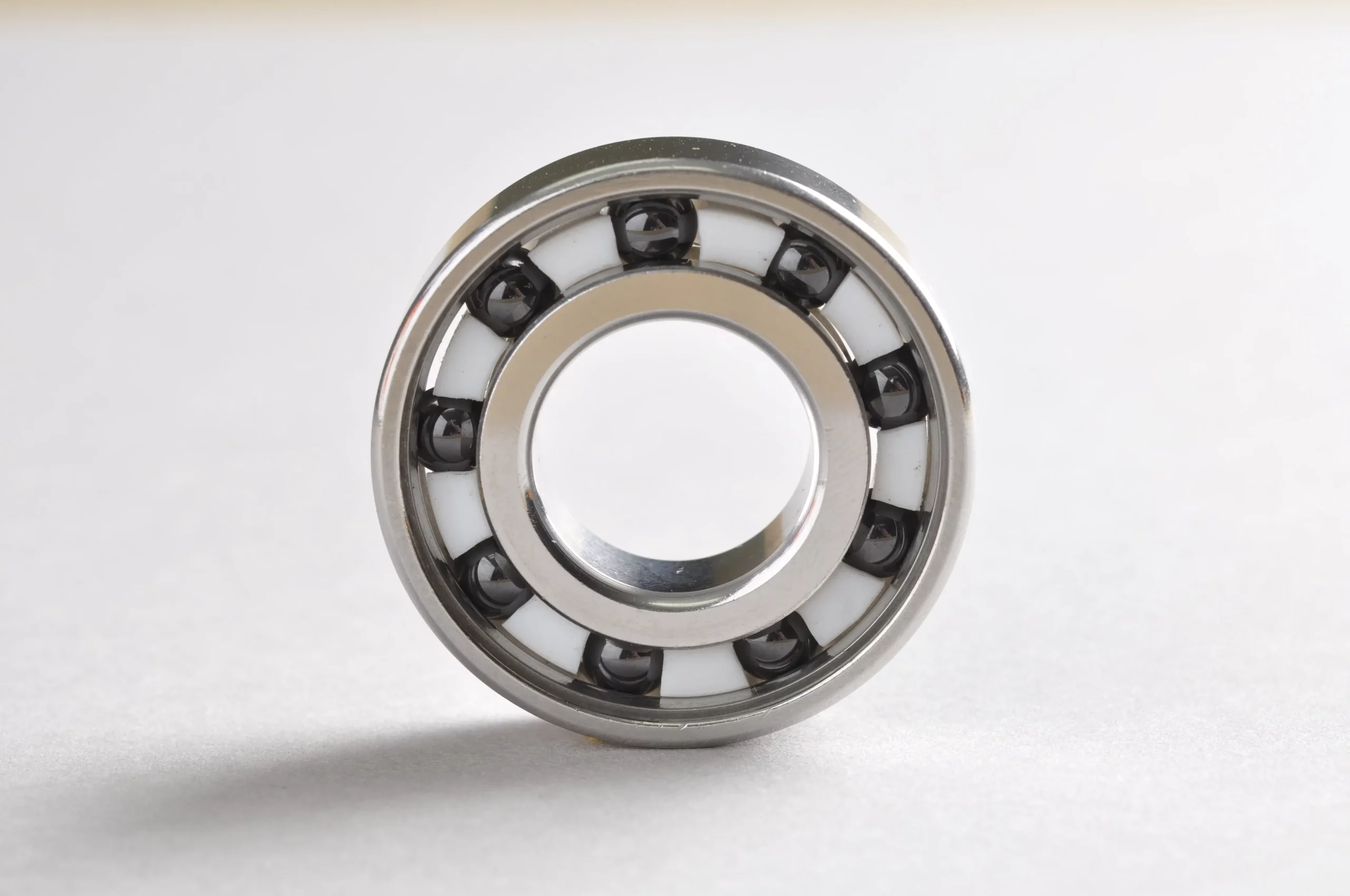

Full Ceramic Ball Bearing

Full Ceramic Ball Bearings are designed for applications operating in extreme special environments where conventional bearings are not suitable for. An anti-friction ball bearing constructed entirely of ceramic material. Inner/outer races and balls are made of either Silicon Nitride (Si3N4), Zirconium Oxide (ZrO2) or Silicon carbide (SiC). Configurations retainers can be made of composite materials such as PEEK, PTFE or full complement versions without retainers are available for your heavily radial loaded applications.

Ceramic Ball Bearing Lubrication

All bearings, whether steel or ceramic, need lubrication. Grease and oil are commonly used lubricants for mixed bearings, but ceramic bearings are not sensitive to the fluctuation of lubrication conditions. For example, ceramic balls can run up to 20 percent faster with the same lubrication compared to steel bearings.

Grease is the recommended lubricant for most ceramic bearing applications except those with high speed operation. Grease is preferred because it is easier to retain on bearings than oil and provides better protection against moisture and pollution.

The most commonly used grease for ceramic bearings is mineral oil-based lithium grease, which is suitable for precision bearings. For high speed, high temperature and extended service life applications, synthetic lubricants are preferred.